ZHONGYANG MACHINERY Co.,Ltd

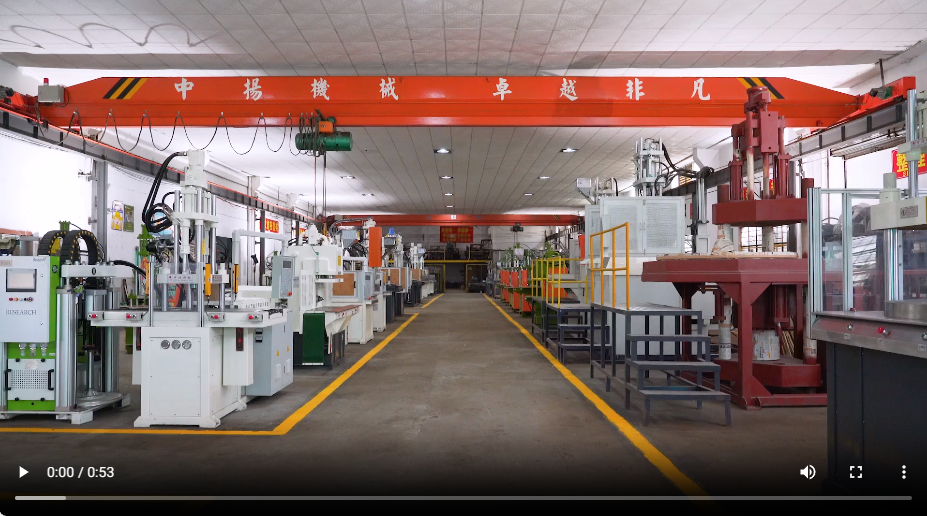

The headquarters of China Machinery Yangxi Co., Ltd. was established in Kaohsiung City, Tainan, Taiwan, and established the Zhongshan factory in the mainland in 2003. The factory covers an area of more than 3900 square meters. It is a professional manufacturer specializing in the research and development, design, manufacturing, sales and service of vertical injection molding machines. Products have already passed the ISO:9001:2015 international quality management system certification and access to the European Union-CE certification.

Zhongyang Machinery has always adhered to the business philosophy of seeking development by science and technology, survival by quality, and winning the market by reputation. It has gathered a group of senior engineers and technical backbone teams with very rich practical experience in the industry. There are hundreds of skilled technicians. Strive for steady development and strive to do a good job in every Zhongyang brand injection molding machine, whether it is electrical components or hydraulic accessories, using well-known brands such as Japan, Italy, Denmark and Taiwan, the carefully built zhongyang machinery zy series injection molding machine: "safe, fast, stable and durable" is famous in the industry. The company absorbs the advanced technology of vertical injection molding machines from Germany, Japan and Taiwan, constantly innovates, improves quality, develops multi-series models, builds its own brand and improves after-sales service quality. Over the years, the products have been deeply trusted and praised by the new and old customers at home and abroad, and also by the industry.

Corporate philosophy: reflect self-worth, create a better life

Development Concept-Innovation, Pragmatism, Bigger, Steady and Stronger

Plant management purpose-people-oriented pursuit of quality credibility first

Forever commitment-first-class quality first-class service

Firm Goal-To Be the Best Injection Molding Machine in China and Foreign Countries

DEVELOPMENT PROCESS

2003

Zhongshan Construction Plant

Company establishment

Joint venture with Taiwan friends to set up factories

Production of 15T-45T injection molding machine

2005

Initial stage

early stage of development

Recruit talents and hire talents

Production of 15T-85T injection molding machine

2010

Promotion to a limited company

Brand forming

Continuous research and development and continuous innovation

Production of 15T-300T injection molding machine

2015

Expansion period

Business Expansion

Established: Hong Kong Zhongyang Technology Group Limited

Guizhou Yueyang Cable Electric Co., Ltd.

Xijiang Qianhu Miao Village Yilan Tingyu Boutique Inn

Xijiang Qianhu Miao Village Yilan Tingyu Resort Hotel

2020

Gratitude Development

enterprise development

Excelsior performance

Start employee equity incentive mechanism

Create brilliance with one heart and one mind

HONOR CERTIFICATE

Products have already passed the ISO:9001:2015 international quality management system certification and access to the EU region-CE certification

COMPANY EXHIBITION

Zhongyang Machinery has been adhering to the business philosophy of seeking development by science and technology, survival by quality, and winning the market by reputation, and has gathered a group of senior engineers and technical backbone teams with rich practical experience in the industry,

Skilled technicians have reached hundreds of people, the company strives to develop steadily, and strive to do a good job in each of the Yang brand injection molding machine

Office Administration

Assembly area

Processing area

Out of the machine (domestic)

Out of the machine (abroad)

Foreign customers

PRODUCT CATEGORIES

AFTER-SALE SERVICE

A, provide free teaching installation, test machine and technical guidance.

B, spare parts warranty for one year, free replacement (except for man-made damage).

C. Service process

The customer calls to reflect the situation → the repairman understands the situation → the telephone video processing or arrives at the equipment site to deal with the problem → after the processing, the customer confirms OK →

Next day's telephone return visit → follow-up irregular telephone tracking service

D. If the machine fails and cannot be solved by telephone, video and other communication methods, the seller shall send personnel to solve the problem, and the seller shall send after-sales technical personnel to the scene:

Zhongshan: inside the city: 24 hours outside the city: 24 hours to 36 hours

Province: within the province: within 24 hours to 48 hours outside the province: within 48 hours to 72 hours

Abroad: Must arrive within the time agreed with the customer

F, service contact information:

24-hour maintenance service contact number:15362953859after sales maintenance service line:0760-22622366

24-hour complaint telephone:13802658525Zhong Sheng Fax:0760-22622123

NEWS CENTER

Mold function of vertical two-color disc injection molding machine

Speed is one of the key factors for the success of thin-wall injection molding. Fast mold filling and high pressure can inject molten thermoplastic...

Silicone machine technical quality workflow

As a kind of production machinery, the silicone machine must pass the quality management standards...

What product is suitable for liquid silicone injection molding machine

Manufacturers of liquid silicone injection molding machines, automatic molding machinery, liquid silicone molding machines...